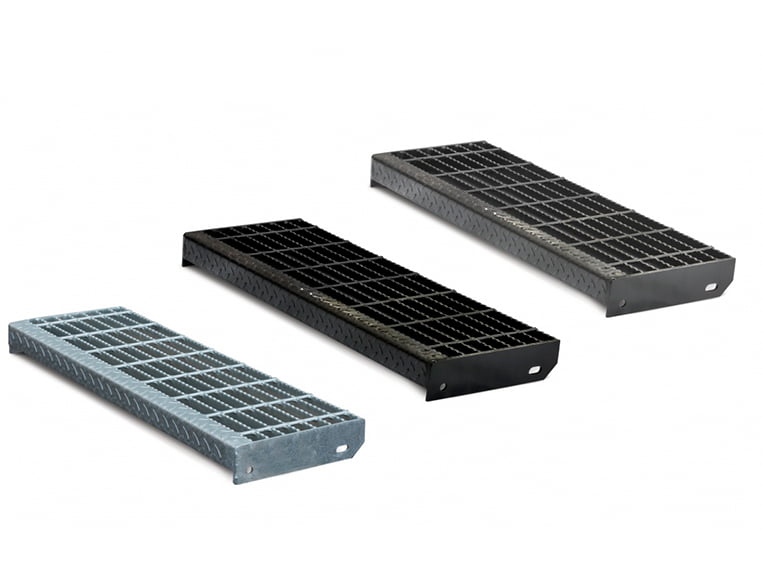

The term finished in the context of electroforged gratings, refers to the final state or condition of the grating after the manufacturing process is complete. It encompasses various aspects related to the appearance, surface treatment, and overall quality of the electroforged gratings.

The term natural finish refers to the untreated or uncoated state of the steel surface, it is commonly used in applications where the natural appearance of steel is desired for architectural, structural, or decorative purposes. The natural finish provides versatility in design, allowing carbon steel to be used in various settings without the need for additional aesthetic treatments. It is a straightforward and cost-effective option for projects where the inherent look of steel is a desirable feature.

Applying a painted finish to carbon steel offers several advantages such as corrosion resistance, the paint acts as a protective barrier, shielding the underlying carbon steel from exposure to moisture, air, and other corrosive elements. This is especially important in outdoor or industrial settings where rusting can occur. Extended lifespan, aesthetic customization, versatility in design, reduced maintenance, improved weather resistance, uniform appearance, resistance to chemicals, easy of cleaning and brand identity.

Galvanizing carbon steel involves coating it with a layer of zinc to provide protection against corrosion. This process, known as galvanization, offers several advantages when compared to untreated or painted finishes. The advantages of this finish include: superior corrosion resistance, longevity, low maintenance, wide range of application, self-healing properties, resistance to rust staining, uniform coating, cost-effective, environmentally friendly, quick application process and excellent adhesion.

Jonathan Navarro –

You choose the material and design that you like the most, I think it is a plus within their service